Every time you start your vehicle, a precise ballet of mechanical components springs into action. At the heart of this performance are small but mighty parts that deliver exactly what your engine needs to run smoothly.

The relationship between your engine’s design and its components follows a simple, elegant rule. Most modern automobiles feature one injector for each cylinder in the powerplant. This direct correlation means counting cylinders reveals your injector count instantly.

Understanding this connection matters more than you might think. These components replaced older carburetor systems to provide better fuel economy, improved performance, and precise delivery. Knowing your specific configuration helps with maintenance decisions and prevents costly repairs.

Whether you drive a compact sedan or a powerful truck, the principle remains consistent. Four-cylinder engines typically use four injectors, while V6 and V8 configurations require six or eight respectively. You can verify your vehicle’s setup through the owner’s manual or online specifications.

This knowledge empowers you as an owner. It helps you understand repair estimates, plan maintenance schedules, and appreciate the engineering behind your daily transportation. The right information can save both time and money.

Key Takeaways

- The number of injectors typically matches the number of cylinders in your engine

- Modern fuel injection systems provide better performance than older carburetors

- Knowing your injector count helps with maintenance and repair decisions

- You can find this information in your owner’s manual or vehicle specifications

- This knowledge helps prevent expensive engine damage over time

- Different engine configurations require different numbers of injectors

Introduction to Fuel Injector Systems

Modern engines rely on sophisticated fuel delivery components that function like precision instruments. These vital parts ensure optimal combustion by managing the flow of energy to your powerplant.

Role and Importance in Engine Performance

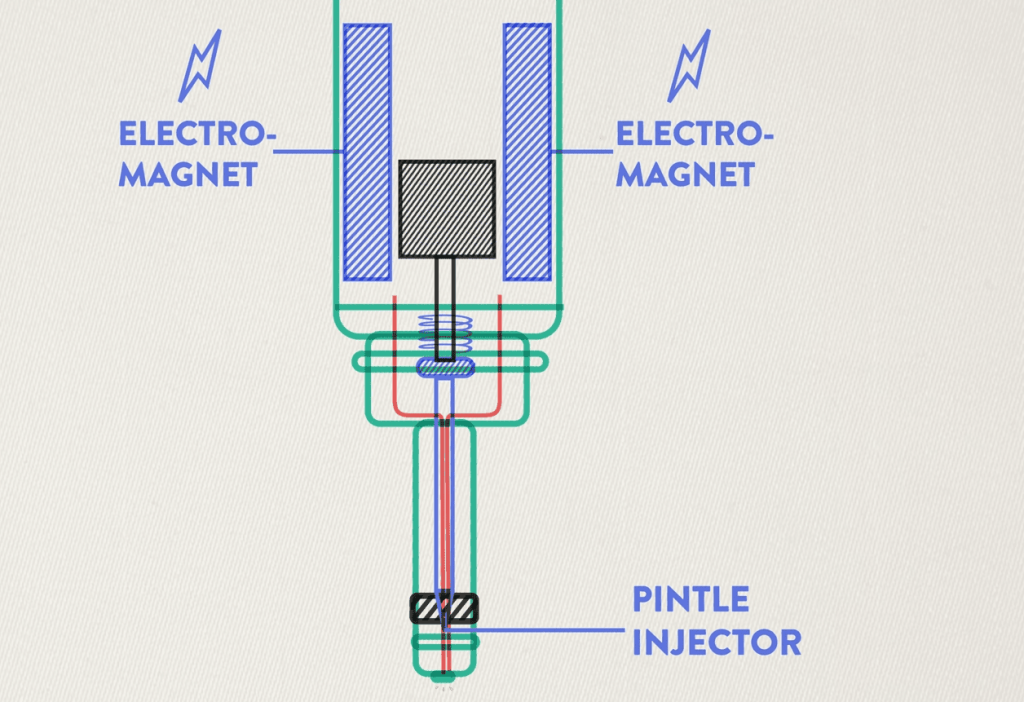

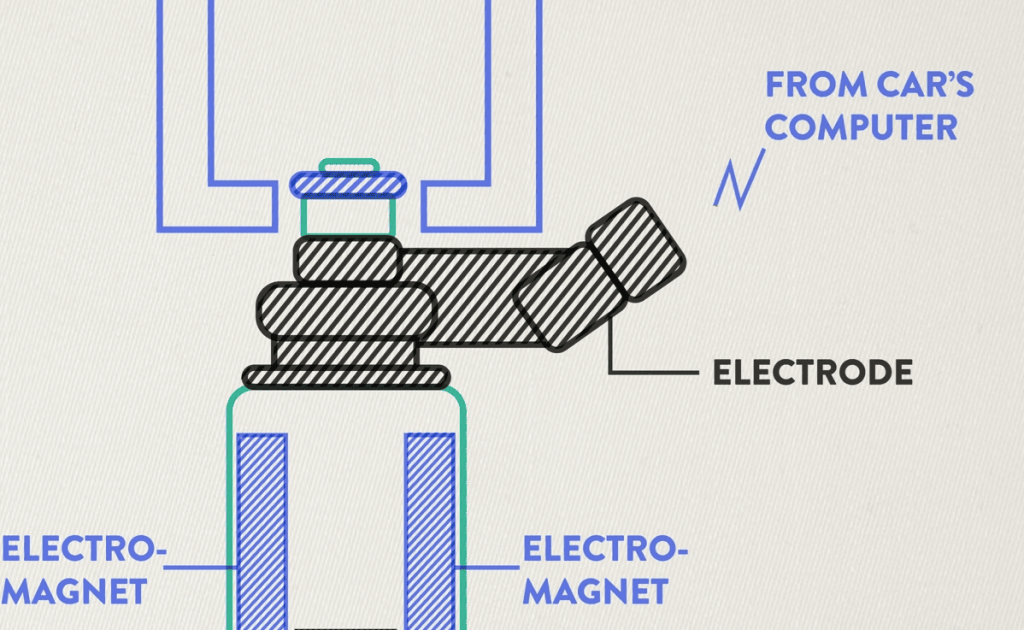

The electronic control unit (ECU) acts as the brain behind the operation. It constantly monitors conditions like temperature and throttle position.

This computer makes adjustments thousands of times per minute. Properly functioning components spray fuel in a perfect cone-shaped pattern.

This ensures even distribution across the combustion chamber. The result is maximum power and efficiency with minimal waste.

Common Symptoms of Fuel Injector Issues

Several warning signs indicate potential problems with these critical parts. Recognizing them early can prevent more serious engine damage.

Rough idling and hesitation during acceleration are common red flags. You might also notice decreased fuel economy and illumination of the check engine light.

| Symptom | Potential Cause | Implication |

|---|---|---|

| Rough idling | Carbon buildup | Uneven fuel distribution |

| Engine misfires | Contaminated fuel | Combustion issues |

| Exhaust smoke | Internal leaks | Serious system failure |

More serious symptoms include unusual engine noises and different colored exhaust smoke. A fuel smell inside the vehicle indicates possible leaks in the delivery system.

These issues typically develop over time due to carbon buildup, poor fuel quality, or normal wear. Regular maintenance helps extend the life of these precision components.

Engine Configurations and Injector Arrangements

Automotive engineers design engines with specific cylinder configurations that directly influence injector placement. The relationship between cylinder layout and fuel delivery components follows consistent engineering principles across different engine types.

Understanding Inline, V6, and V8 Setups

Inline engines position cylinders in a straight row. This compact design typically features injectors mounted directly above each cylinder. Four-cylinder engines use four injectors arranged sequentially.

V-shaped engines split cylinders into two banks angled toward each other. A V6 configuration places three injectors on each bank. V8 engines require four injectors per side for balanced performance.

Injector Placement and Fuel Injection Methods

Multi-point injection systems mount components in the intake manifold. These systems spray fuel toward the intake valves before it enters the combustion chamber. This method provides reliable performance across various engine types.

Gasoline direct injection represents a more advanced approach. This technology positions injectors directly inside the combustion chamber. The result is improved precision and efficiency during the combustion process.

Comparing Gasoline Direct Injection and Multi-Point Injection

Different injection systems offer distinct advantages for modern engines. The table below highlights key differences between these two primary technologies.

| Feature | Multi-Point Injection | Gasoline Direct Injection |

|---|---|---|

| Injector Location | Intake manifold | Combustion chamber |

| Fuel Efficiency | Good | Excellent |

| Complexity | Moderate | High |

| Maintenance Cost | Lower | Higher |

Both systems maintain the fundamental principle of one injector per cylinder. This ensures proper fuel distribution regardless of the specific injection method used in your vehicle’s engine.

how many fuel injectors does a car have: Factors and Considerations

Your engine’s cylinder arrangement holds the key to identifying proper component quantities. Most vehicles follow a straightforward pattern that makes determining the right number simple.

Matching Component Count to Engine Cylinders

The standard configuration uses one delivery component for each cylinder. This ensures balanced performance across all combustion chambers.

Four-cylinder engines typically require four components. V6 and V8 configurations need six or eight respectively.

You can verify your specific setup through your owner’s manual or online specifications. This information helps with maintenance planning and repair decisions.

Special Cases and Advanced Technologies

Some high-performance vehicles feature dual components per cylinder. These advanced systems provide enhanced precision and power output.

The electronic control unit manages each component’s operation. It calculates optimal delivery based on real-time driving conditions.

Replacement costs vary depending on your vehicle type and engine configuration. Proper maintenance extends the life of these critical parts.

Conclusion

Knowing what’s happening under your hood transforms you from a passive driver to an informed vehicle owner. The simple rule—one injector per cylinder—gives you immediate insight into your vehicle’s setup. This knowledge helps you understand repair estimates and communicate effectively with mechanics.

Recognizing early warning signs prevents minor issues from becoming major repairs. Rough idling, decreased performance, or unusual engine sounds signal potential injector problems. Addressing these symptoms promptly protects your engine investment and maintains reliability.

Regular maintenance extends the life of your fuel injection system. Using quality fuel and scheduling periodic cleaning keeps these precision components working efficiently. Whether you drive a compact sedan or powerful truck, understanding your fuel system empowers smarter maintenance decisions for years of dependable service.