Did you know that Mercedes-Benz Group AG is one of the few automotive manufacturers that designs and builds its own gearboxes? This gives them complete control over quality and innovation in their sophisticated systems.

The company uses a unique numbering system from 720 to 725 to identify their various gearbox designs. These include automatic, dual-clutch, continuously variable, and automated manual options.

Understanding what’s under your hood helps you make smarter decisions about maintenance and performance. Whether you drive a passenger car, SUV, or light commercial vehicle, this knowledge empowers you.

This guide takes a friendly approach to demystify the technical aspects of these critical components. We’ll explore how they transfer power from the engine to the wheels, contributing to the brand’s reputation for excellence.

From basic distinctions to the latest hybrid and electric integrations, we cover everything you need to know about these advanced systems and how they enhance your driving experience.

Key Takeaways

- Mercedes-Benz Group AG designs and manufactures its own gearboxes in-house

- The company uses a numbering system from 720 to 725 to identify different gearbox designs

- These systems are used across passenger cars, SUVs, and light commercial vehicles

- Understanding your vehicle’s gearbox helps with maintenance and performance decisions

- The technology significantly impacts your driving experience and vehicle reliability

- Different designs include automatic, dual-clutch, continuously variable, and automated manual options

- Knowledge of these systems helps appreciate the engineering behind Mercedes models

Understanding Mercedes Transmission Basics

Modern driving comfort relies heavily on an intricate component system that manages the flow of power from motor to wheels. This sophisticated assembly ensures smooth acceleration and responsive handling in every driving situation.

The Role of Transmissions in Vehicle Performance

Think of your gearbox as the intelligent translator between engine language and wheel needs. It converts high-speed rotation into appropriate torque for different driving conditions.

The system gives you precise control over speed and direction. Whether accelerating from a stop or cruising on the highway, it optimizes performance by selecting the perfect gear ratio.

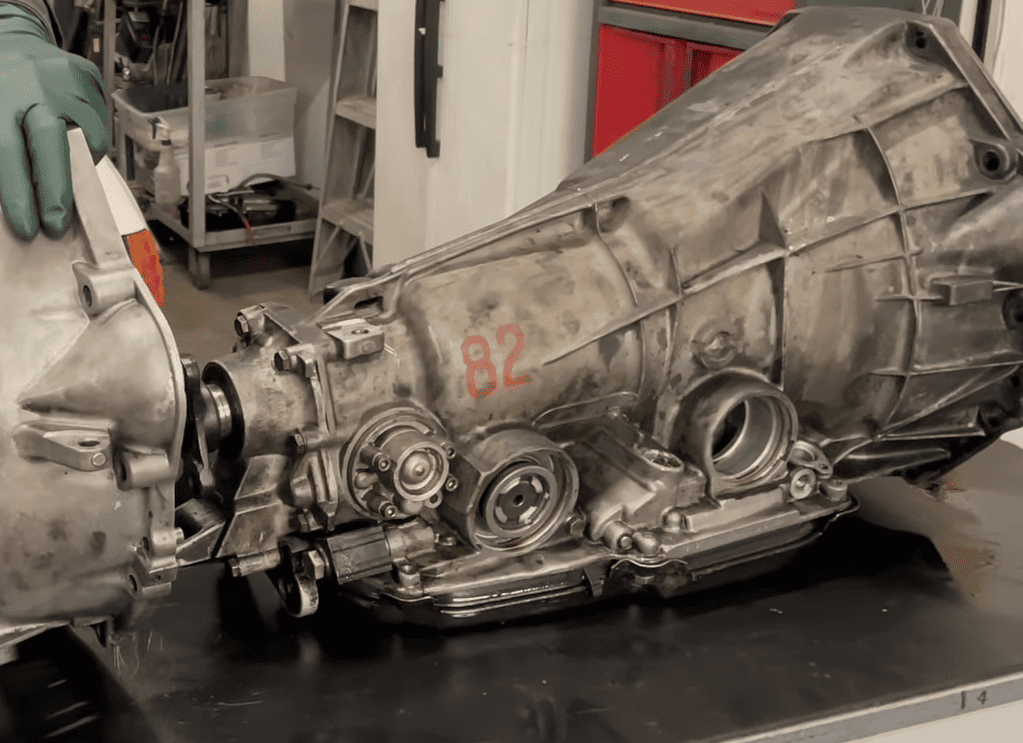

Key Components: Torque Converter, Planetary Gears, and the Hydraulic System

Three essential parts work together seamlessly. The torque converter acts as the fluid coupling between engine and gearbox, allowing smooth power transfer even when stationary.

Advanced planetary gear sets provide multiple ratios for optimal performance. These sophisticated arrangements engage and disengage to match your driving demands.

The hydraulic system serves as the nervous system, using special fluid for both lubrication and precise gear control. This triple-component harmony delivers the responsive experience drivers expect from premium vehicles.

Understanding these elements helps appreciate why regular maintenance matters. Each part contributes to the reliable power transfer from engine shaft to wheels that defines quality automotive engineering.

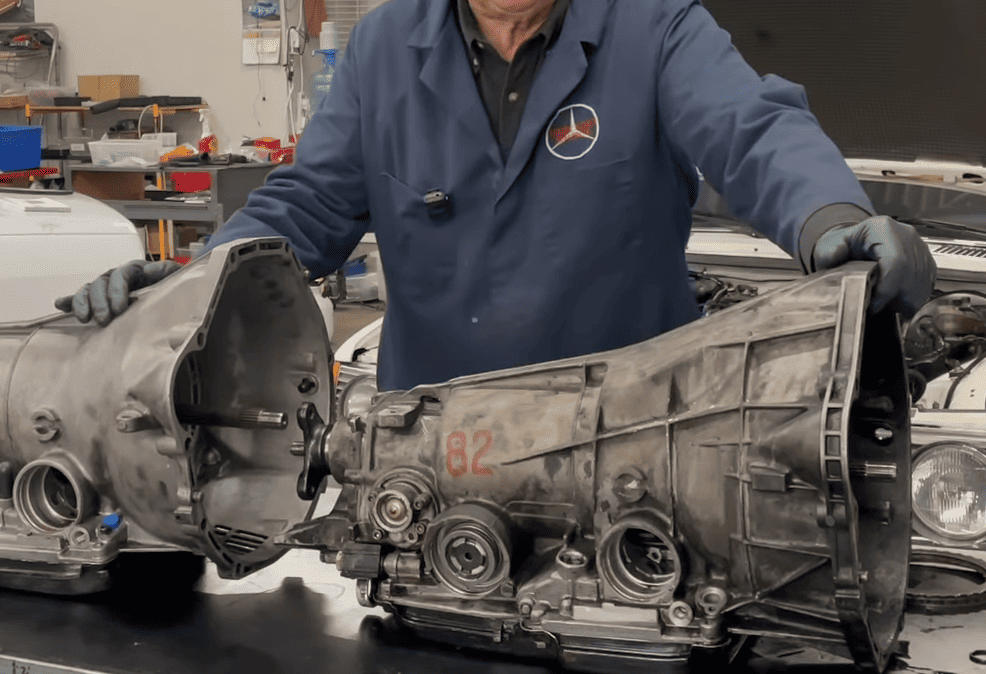

The Evolution of Mercedes Transmission Systems

Over decades, the systems that transfer power in Mercedes vehicles have undergone a remarkable transformation. This evolution reflects a continuous pursuit of smoother, more efficient, and more intuitive driving.

Historical Overview: Manual and Early Automatic Models

Initially, drivers relied on manual gearboxes. These units, identified by codes like the 6-speed G56, required direct driver involvement with a clutch.

The introduction of automatic systems was a major leap forward. These units could select gear ratios independently based on speed and load.

Mercedes established a clear numbering system to track this development. Manual gearboxes used a “G” prefix. For automatics, the company used the 722 series.

- Manual Gearboxes: Used a “G” prefix (e.g., G56).

- Automatic Gearboxes: Used the “722” series number.

Generations and Technological Milestones

The number after the decimal point in the 722 series indicates the generation. For example, 722.1 was the first generation, while 722.8 represents the eighth.

Each new generation brought significant improvements. Engineers focused on shift quality, fuel economy, and durability over many years.

A pivotal moment came in 2019. The company discontinued the production of manual gearboxes for its cars, fully committing to advanced automatic technology for all future models.

This long-term development, from simple 3-speed units to modern 9-speed designs, showcases a relentless focus on refinement. It ensures every model delivers a superior driving experience.

Mercedes Transmission Types: A Detailed Buyer’s Guide

When selecting your next premium vehicle, the gearbox technology plays a crucial role in determining overall performance characteristics. Understanding the available options helps match your driving style with the right system.

Comparing Automatic and Manual Options

While manual gearboxes offered direct control, modern automatic systems provide superior convenience and fuel economy. The brand’s current lineup focuses exclusively on advanced automatic transmissions for optimal driving experience.

Different series cater to specific needs. The 722.6 automatic transmission served vehicles from 1997-2009, while the revolutionary 725.0 introduced the world’s first 9-speed design in 2013. Each type delivers distinct performance benefits.

Understanding Model-Specific Variations

The same transmission series adapts to different models through customized calibrations. This ensures optimal pairing with various engine configurations, from efficient 4-cylinder to powerful 12-cylinder options.

Whether you prefer rear-wheel or all-wheel drive, there’s a specialized system. The 724.0 dual-clutch unit excels in front-wheel drive applications, offering lightning-fast gear changes for sporty cars.

“The right gearbox transforms a good vehicle into a great driving companion, balancing efficiency with responsive performance.”

Considering your typical driving conditions and performance expectations will guide you toward the ideal model configuration. This knowledge empowers smarter purchasing decisions.

Key Components and Innovations in Mercedes Transmissions

At the heart of every modern premium vehicle lies a sophisticated network of electronic components that work in perfect harmony. These advanced systems transform raw engine power into smooth, responsive driving experiences. The integration of digital intelligence with mechanical precision represents the cutting edge of automotive engineering.

Electronic Control Unit (ECU) and Adaptive Shift Technology

The ECU acts as the intelligent brain of the entire system. This computerized unit constantly monitors vehicle speed, engine load, and driver behavior. It makes split-second decisions to optimize every gear change for maximum performance.

Adaptive shift technology takes personalization to new levels. The system learns your unique driving style over time. Whether you prefer spirited acceleration or smooth cruising, it adjusts shift patterns accordingly.

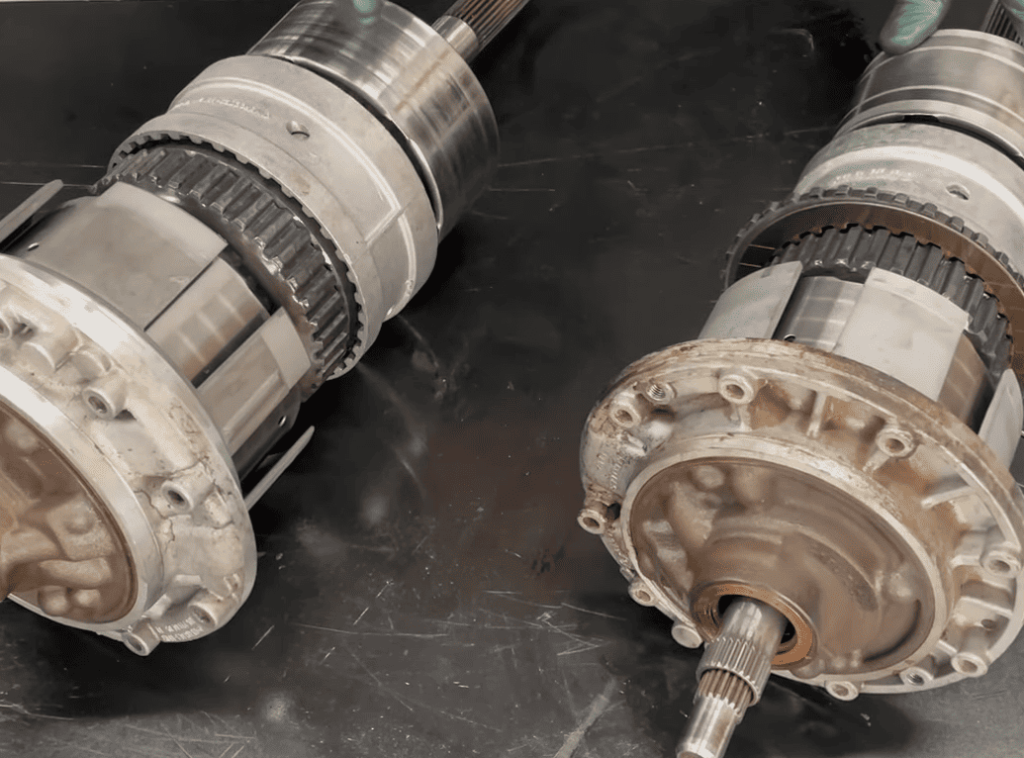

Advanced Clutch Systems and Dual-Clutch Setups

Modern clutch designs represent significant engineering breakthroughs. Dual-clutch systems use two separate units—one for odd-numbered gears and another for even gears. This allows pre-selection of the next gear for lightning-fast changes.

The synergy between electronic control and mechanical components creates seamless power delivery. Shift solenoids work with the ECU to execute perfect gear engagements. This harmony ensures optimal torque transfer in every driving situation.

| Feature | Traditional Systems | Modern Electronic Innovation |

|---|---|---|

| Control Method | Hydraulic pressure and mechanical linkage | Computerized ECU with sensor input |

| Shift Adaptation | Fixed programming | Learning algorithms that adapt to driver behavior |

| Gear Change Speed | Standard hydraulic timing | Millisecond precision with pre-selection |

| Efficiency Optimization | Basic economy modes | Real-time adjustment for fuel efficiency |

These innovations work together to deliver exceptional driving dynamics. The system ensures your vehicle operates within the engine’s optimal power range. This intelligent approach maximizes both performance and efficiency in every situation.

Maintenance and Care for Optimal Performance

Keeping your vehicle’s gear system in peak condition requires understanding the specific maintenance needs for your particular model. Proper care ensures reliable performance throughout the life of your car.

Fluid Checks, Oil Change Intervals, and Genuine Parts

Regular fluid maintenance is crucial for longevity. Different series have unique requirements based on production years and performance levels.

Using the correct oil grade at the right time prevents premature wear. High-performance models often need more frequent changes.

| Series | Change Interval | Oil Grade | Special Notes |

|---|---|---|---|

| 722.6 (1997-2000) | 80,000 km | 236.14 | Early production models |

| 722.6 (2000+) | 100,000 km | 236.14 | Later production years |

| 722.8 | 60,000 km | 236.20 | Daimler specific recommendation |

| 722.9 FE | 80,000-120,000 km | 236.15 | Special blue fuel-efficient oil |

| 725.0 | 80,000 km | 236.17 | Natural gas-based oil |

Tips for Preventing Common Transmission Issues

Avoid harsh driving habits like sudden acceleration. Address warning signs immediately to prevent major repairs.

Use only genuine parts during service. Qualified technicians understand specific requirements for each series.

Following these guidelines extends the life of your vehicle’s system. Proper maintenance saves money in the long run.

Performance, Efficiency, and Driving Experience

Optimizing both performance and economy represents one of the greatest engineering challenges in modern vehicle design. Today’s advanced systems achieve remarkable balance through intelligent computer management.

Enhancing Fuel Economy and Transmission Responsiveness

Modern gearbox technology continuously monitors multiple parameters to optimize efficiency. The system selects ideal gear ratios based on engine load, speed, and driving conditions.

The 722.9 FE system delivers approximately 7% fuel savings compared to earlier designs. This translates to about 0.6 liters per 100 km for larger models.

Dual-clutch technology in the 724.0 unit achieves 9% lower fuel consumption. It provides quicker, more responsive shifts that enhance the overall driving experience.

| System | Fuel Efficiency Gain | Key Feature | Driving Benefit |

|---|---|---|---|

| 722.9 FE | 7% improvement | Advanced shift programming | Optimal power delivery |

| 724.0 DCT | 9% reduction | Dual-clutch design | Lightning-fast shifts |

| 725.0 | Exceptional economy | Nine-speed configuration | Enhanced comfort |

Paddle shifters mounted on the steering wheel offer manual control without removing hands from the wheel. This combines automatic efficiency with sporty engagement when desired.

The seamless integration between components ensures every shift optimizes both fuel economy and smoothness. The system anticipates needs based on throttle input and road conditions.

Innovative Technologies and Future Developments

Future mobility solutions demand sophisticated integration between traditional mechanical systems and electric propulsion. The automotive industry’s shift toward electrification represents one of the most significant transformations in recent history.

Manufacturers are investing heavily in research to create systems that bridge conventional and electric power sources. This evolution ensures drivers experience seamless performance regardless of their vehicle’s powertrain configuration.

Integration with Hybrid Drives and Electrification Trends

The 725.1 automatic transmission exemplifies this forward-thinking approach. It features integrated components specifically designed for hybrid drive systems, representing a major milestone in transmission development.

Hybrid integration presents unique engineering challenges. These advanced systems must handle both combustion engine power and electric motor torque simultaneously.

They also manage regenerative braking and seamless power source switching. The goal is to make these transitions completely transparent to the driver.

| Feature | Traditional Transmission | Hybrid-Ready System |

|---|---|---|

| Power Source Handling | Single combustion engine | Dual power sources (engine + electric) |

| Regenerative Braking | Not supported | Integrated energy recovery |

| Shift Programming | Fixed algorithms | Adaptive AI-based optimization |

| Efficiency Focus | Fuel economy only | Combined energy efficiency |

Future transmission development will continue improving efficiency while reducing weight. The brand maintains its commitment to refinement across all vehicle models.

Advanced software and control systems are becoming increasingly important. Artificial intelligence helps optimize shift patterns and predict driver intentions in real-time.

This technological evolution ensures that whether driving conventional, hybrid, or fully electric vehicles, customers will experience the same responsive performance. The end goal remains delivering exceptional driving pleasure through intelligent engineering.

Conclusion

Understanding your vehicle’s powertrain system transforms how you interact with and maintain your premium automobile. This knowledge empowers smarter decisions whether purchasing new cars or caring for current models.

The evolution from engaging manual systems to sophisticated automatic transmission technology showcases the brand‘s commitment to innovation. Different transmissions across various vehicles demonstrate thoughtful engineering for every driving need.

Proper maintenance remains crucial for optimal performance and longevity. Following specific service intervals ensures your transmission operates smoothly for years to come.

As technology advances toward electrification, the core principles of smooth power delivery and efficiency will continue. This commitment ensures every journey delivers an exceptional driving experience that defines the premium automotive experience.